Rapid Mixer Granulation Machine is used for homogeneous mixing of granulation powder used for the production of tablets. It is also used for the process of wet mixing and fast dry, humidifying of the powder in chemical, cosmetic, food, plastic, pharmaceutical, general mixing industries

DESCRIPTION:

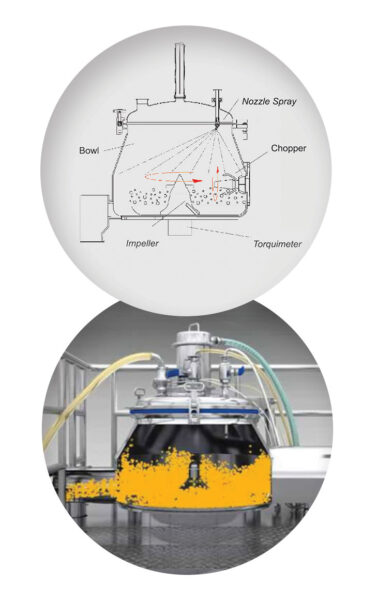

The Rapid Mixer Granulator performs dry mixing & wet granulating by basic design of the special three arms of the mixing impeller and sequences of the mixing process in the cylindrical mixing drum with a rounded connection to the base plate, achieving another special effect.

Dry mixing is the first step of the process. Once the products are mixed by the bottom drive rotating tool (impeller), a binder is added to the product. The binder can be sprayed in as part of a binding solution or it can be added in dry form. After this Mixing process, the spraying process occurs through one or more spray nozzles, and by mixing action of the main mixing tool (impeller) and the chopper blade it is quickly dispersed into the product.

FEATURES & HIGHLIGHTS

- Air purge sealing for main shaft and granulator shaft.

- Homogeneous binder distribution

- Impeller lifting to a height of 150 mm from bowl bottom for easy cleaning

- Lifting. swiveling and tilting of lid assembly by 90° for easy cleaning of lid internals.

- Modular design for chopper blades for optimum results

- Spray nozzle and peristaltic pump for binder granulating liquid addition.

- Jacket for cold /hot water circulation.

- Integrated cleaning system for WIP &CIP.

- PLC-based control with recipe administration and visualization.

- Suitable for container and vacuum transfer product infeed.

- Models are available from 25 Ltrs. To 1250 Ltrs. capacity.

- Short batch time & reduced cleaning time.

- The seal housing and drive shaft may be flushed with cleaning water, which is then drained away from the machine through built-in drain tubes.

- GMP/Flameproof/ SS 316 construction on demand.

- Seven different layouts to suit machine placement as per the room layout.

- Enclosed moving parts. Maximum care has been taken to ensure machine safety.

- Can be used in the fields of pharmaceuticals, bulk drugs & special foodstuffs.

- Available with Auto/Manual Controls.

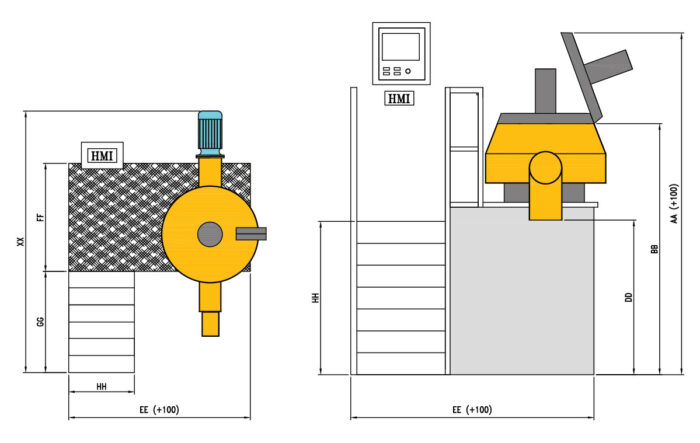

TECHNICAL DRAWING

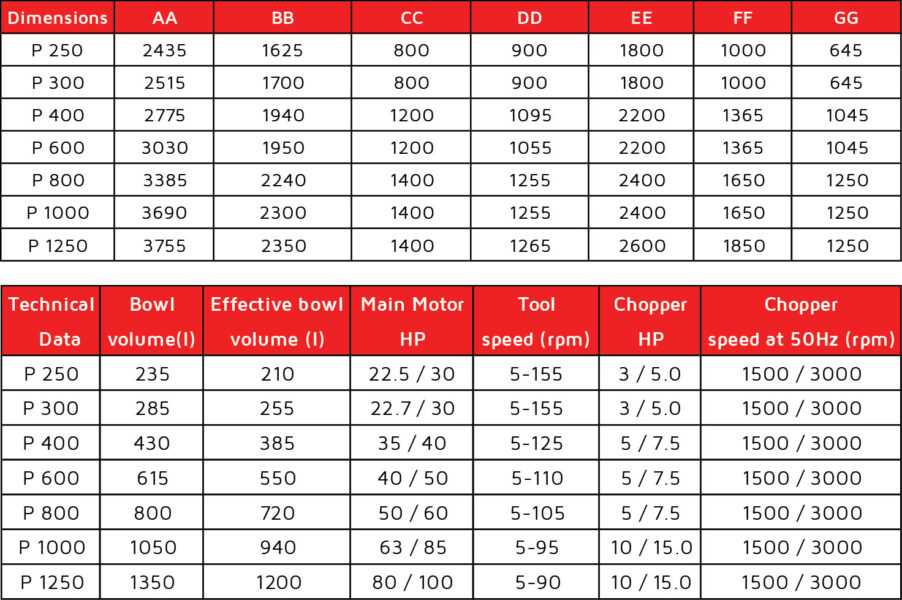

TECHNICAL SPECS