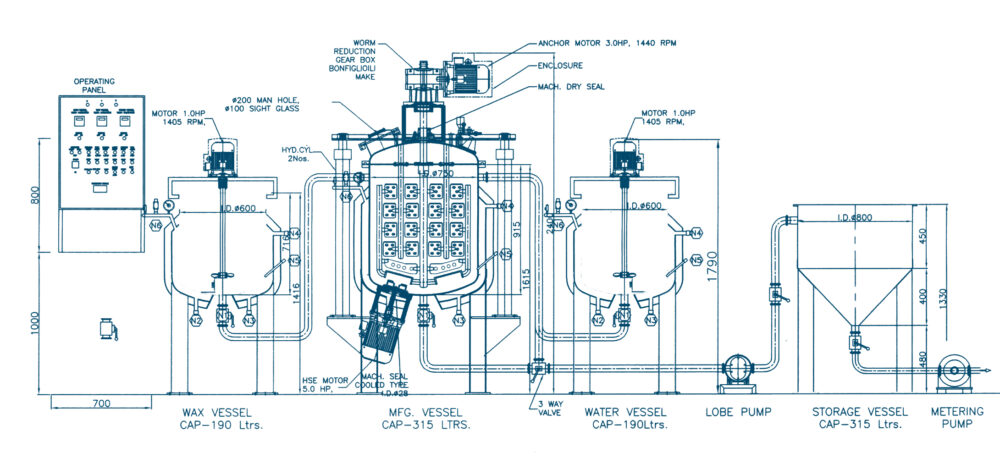

Essential ingredients for the ointment/gel/toothpaste are glycol, water & wax. The calculated volume of glycol is heated in the jacketed Vessel & the required quantity of wax is melted in a jacketed vessel.

DESCRIPTION:

Heating/cooling and insulated jackets complete with temperature control and safety equipment. Contra Rotary agitator for high viscose products. Short loop product Re-Circulation for smaller batch sizes. The water phase & wax phase has high shear mixers & Manufacturing. The vessel is installed with an Anchor agitator with a high shear homogenizer/ emulsifier. Hydraulic lifting on manufacturing vessel top dish to facilitate product recovery. Process piping with transfer panel design for automated plants. Cleaning in place cycle with validation protocols. PLC-based operations with automation, recipe administration & visualization. Vacuum Line fully flushed for sanitation purposes.

FEATURES & HIGHLIGHTS

- Models range from 5OL to 20,000 L capacity, automatic untouched process or in semi-automatic models as per GMP I cGMP manufacturing standards with documents

- Three Tank Process: Sugar Melting Vessel Manufacturing Vessel- Storage Vessel

- The Tank can be mounted on legs or lugs as required

- Stirrer/Impeller type high-speed stirrers, paddle type slow speed stirrer for low viscous liquids & anchor type stirrer for high viscous liquids

- Jacket or Limpet for steam heating. AII Vessels are insulated

- Homogenizer for Homogenous Online /in line Mixing of Products I Suspensions Bottom homogenizer I stirrer optional

- Electro-polished interconnecting pipeline and TC fittings for Easy cleaning &Assembly

- Complete untouched process optional with the auto transfer of products& ingredients

- Optional vacuum arrangement provided on requirement

- In-built CIP system for cleaning and washing vessels from inside

- Load cell-level Indicators can be integrated with the system

- Optimized design & fully Automated PLC based operations

- Complete documentation & certificates to ensure compliance with regulatory bodies with DO, OQ, IQ, FAT & SAT

APPLICATIONS

The liquid Oral Plant is also referred to as Syrup Manufacturing Plant.

- Syrups

- Oral Liquid

- Suspensions

OINTMENT PLANT INCLUDES

- Sugar Melting Vessel

- Storage Vessel

- Vacuum System for transfer

- Top & Bottom Entry Mixer

- PLC Control Panel

- Manufacturing Vessel

- Online Sugar Syrup Pre-Filter

- Zero hold-up Filter

- Transfer Pumps

TECHNICAL DRAWING