Optimizing Your Powder Processing Equipment: The Ultimate Guide

Powder processing equipment is indispensable across various industries, including pharmaceuticals, food processing, and chemical manufacturing. Efficiency in powder processing isn’t just about convenience; it’s a crucial factor in maintaining product quality, maximizing productivity, and minimizing waste. In this blog, we’ll delve into the intricacies of optimizing your powder processing equipment to elevate performance and streamline operations.

Understanding Powder Processing Equipment

Before diving into optimization strategies, let’s familiarize ourselves with the different types of powder processing equipment available:

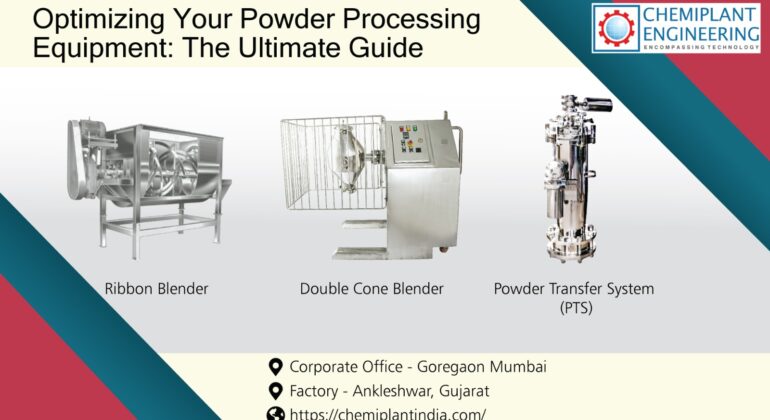

- Ribbon Blender: The Ribbon Blender, equipped with a horizontal, ribbon-shaped agitator, is commonly used for mixing powders, granules, and other dry materials. Its gentle blending action ensures homogeneity without damaging fragile ingredients.

- Double Cone Blender: Renowned for its gentle tumbling action, the Double Cone Blender is ideal for blending powders and granules while maintaining particle integrity. Double Cone Blenders provide an efficient but gentle blending action. Though the mixing time may be slightly longer, the blending efficiency remains high. Additionally, blending action can be intensified by providing asymmetric cones due to their irregular shape. Optimum performance is achieved by maintaining the internal angle of the lower cone at 60°, ensuring good product discharge. Moreover, working volumes typically amount to 60% of total volumes, optimizing blending effectiveness while conserving space.

- Powder Transfer System (PTS): The PTS offers a comprehensive solution for efficiently and safely handling powdered materials. With features such as top and bottom supports providing a completely enclosed structure, silent and precise lifting and positioning, and dust-free operation, the PTS ensures optimal containment and protection throughout the transfer process. It’s widely used in various industries, including pharmaceuticals, chemicals, cosmetics, and food processing.

Optimization Strategies

Now, let’s explore key strategies for optimizing your powder processing equipment:

- Regular Maintenance: Just like with any machinery, regular maintenance is crucial for keeping your powder processing equipment running smoothly. This means scheduling routine inspections to identify any wear and tear, lubricating moving parts to prevent friction and damage, and promptly addressing any issues that arise. By staying on top of maintenance tasks, you can prevent unexpected breakdowns and ensure that your equipment operates efficiently for years to come.

- Adjust Settings: Every powder processing application is unique, so it’s important to fine-tune the settings of your equipment to suit your specific needs. This might involve experimenting with different mixing speeds, blending times, and batch sizes to achieve the desired results. By finding the optimal settings for your particular application, you can maximize efficiency and quality while minimizing waste.

- Handle Materials Carefully: Proper material handling is essential for maintaining product integrity and preventing contamination in powder processing operations. This includes using appropriate containment systems, such as dust collection units, to capture airborne particles and keep your workspace clean. By minimizing product loss and reducing the risk of contamination, you can ensure consistent product quality and avoid costly production setbacks.

- Check Quality: Quality control is a critical aspect of powder processing to ensure that your products meet the necessary specifications and standards. This involves conducting regular sampling and testing of your products to verify consistency and adherence to quality requirements. By monitoring product quality closely, you can identify any issues early on and take corrective action to maintain high standards and customer satisfaction.

- Train Your Team: Proper training is essential for ensuring that your staff knows how to operate and maintain powder processing equipment effectively. This includes providing comprehensive training programs for equipment operators and maintenance staff to familiarize them with the equipment’s operation, safety protocols, and maintenance procedures. Well-trained personnel are better equipped to identify potential problems proactively, troubleshoot issues as they arise, and implement corrective actions promptly, minimizing downtime and maximizing productivity.

Conclusion:

Optimizing your powder processing equipment is essential for achieving operational excellence and maintaining a competitive edge in today’s market. By implementing the strategies outlined in this blog and leveraging advanced equipment such as the Ribbon Blender, Double Cone Blender, and Powder Transfer System, you can enhance efficiency, improve product quality, and drive success in your powder processing operations.

At Chemiplant Engineering, we specialize in providing innovative solutions for powder processing challenges. Whether you’re looking to upgrade your existing equipment or optimize your production processes, our team of experts is here to help. Contact us today to unlock the full potential of your powder processing operations.