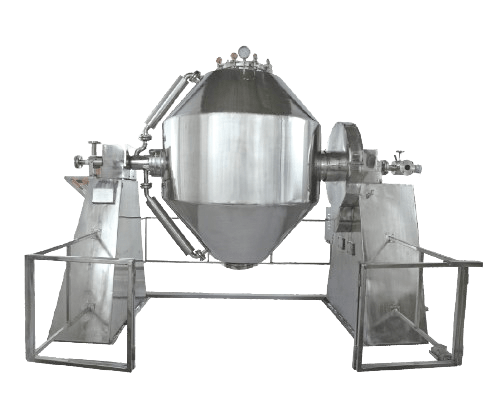

A Comprehensive Guide to Double-Cone Vacuum Dryers

Chemiplant’s Double Cone Vacuum Dryers stand as a pinnacle for the efficient removal of water/solvents from wet powder subsequent to filtration processes. Renowned across the Chemicals, Fine Chemicals, Intermediate, and Pharmaceutical sectors, these dryers cater to a broad spectrum of products, including both crystalline and amorphous substances.

The versatility of Double Cone Dryers is unmatched, attributed to their ability to achieve low drying times, operate at low temperatures, and attain exceedingly low final moisture levels in products. Adhering to cGMP and FDA standards, these dryers ensure compliance with stringent industry regulations.

Incorporating lump breakers within the dryer enhances the product’s surface area for evaporation. Strategically positioned, these lump breakers oscillate within the product during dryer rotation, thereby expediting drying time and guaranteeing minimal moisture content. Equipped with specialized mechanical seals, the lump breaker shafts ensure an airtight vacuum within the system.

Advantages of Double Cone Vacuum Dryer include:

- Reduced drying times

- Enhanced uniformity and homogeneity of dried products

- Maximum operator and environmental safety

- Effortless unloading of products with minimal manpower

- Exceptionally low final moisture content in dried products

- Operating at low temperatures

- Facilitated internal cleaning due to the unique shape of the dryer body

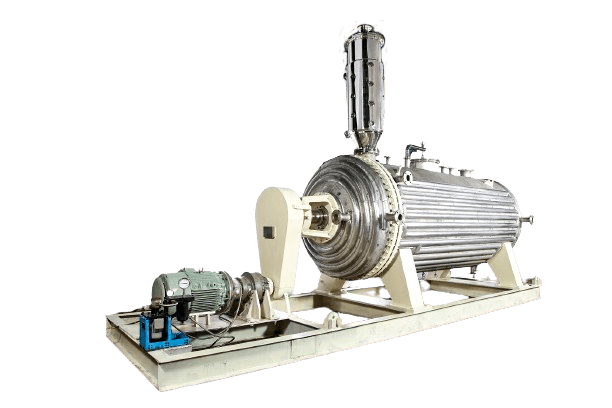

Complementing the Dryer Systems, Chemiplant offers an array of accessories meticulously designed to cater to various batch sizes. These include heating units utilizing hot water or hot oil generation systems, condensing units with appropriate receivers for recovered solvents, high vacuum pump units from reputable manufacturers, and control panels integrated with PLC and SCADA software, ensuring batch reproducibility and seamless integration with DCS systems.

Working Principle & Construction:

Chemiplant’s Double Cone Dryers feature a bi-conical rotating chamber mounted on a sturdy pedestal. Raw materials are charged in batches and subjected to indirect heating through a jacket, facilitating drying operations at low temperatures under vacuum.

Material of Construction:

Available in stainless steel grades of AISI 316/316L and AISI 304/304L, with the provision for other grades such as Hastelloy C276/C22 upon request, Chemiplant’s Double Cone Dryers ensure durability and reliability. Vapors generated within the dryer chamber are efficiently removed through vacuum, effectively reducing moisture content in the product. Specially designed micro filters prevent solids from escaping the system, while a nitrogen purging system further enhances operational safety.

Applications:

With a diverse range of applications, Double Cone Vacuum Dryers find extensive usage across various industries:

- Pharmaceutical Industry: Ideal for drying active pharmaceutical ingredients (APIs), excipients, and intermediates.

- Fine Chemicals: Suitable for drying fine chemicals and other chemical substances.

- Food Industry: Versatile in drying a wide array of food products, including crystalline and amorphous substances.

- Other Applications: Utilized in the production of antibiotics, APIs, aroma, biotechnology products, caffeine, colorants, cosmetics, crystals, deontological resins, diet food, food additives, peptides, pharmaceutical excipients, pharmacy synthesis, preservatives, saccharine, sweeteners, tablets, and vitamins.

In summary, Chemiplant’s Double Cone Vacuum Dryers epitomize efficiency, reliability, and compliance, catering to the diverse needs of industries with precision and excellence.