How to Revolutionize Pharmaceutical Manufacturing with Ointment and Liquid Oral Plants

In the realm of pharmaceutical and cosmetic manufacturing, precision, efficiency, and adherence to stringent quality standards are paramount. Chemiplant Engineering has been a pioneering force in this arena for over four decades, under the dynamic leadership of Mr. Ved Kalra. From its humble beginnings in Mumbai, the company has grown into a professionally managed, customer-centric entity with a sprawling 50,000 sq. ft. manufacturing unit in Ankleshwar, Gujarat. Specializing in high-quality process equipment, Chemiplant Engineering is renowned for its commitment to timely delivery, optimum quality, and competitive pricing. Let’s explore two of their innovative manufacturing plants, the Cream & Ointment Manufacturing Plant and the Liquid Oral Manufacturing Plant, delving into their applications, features, outputs, and advantages.

Cream & Ointment Manufacturing Plant

Application:

Pharmaceuticals: Creams, Emulsions, Gels, Ointments

Cosmetics: Lotions, Shampoo, Toothpaste

Concept: The plant facilitates the manufacturing of creams, gels, and ointments by blending basic ingredients such as glycol, water, wax, and active ingredients in precise proportions. The process involves heating the glycol and melting the wax in jacketed vessels, followed by the addition of active ingredients in the manufacturing vessel to produce the desired product.

Salient Features:

- High shear mixers for the water phase and wax phase.

- Anchor agitator with a high shear homogenizer/emulsifier in the manufacturing vessel.

- Heating/cooling jackets with temperature control and safety equipment.

- Hydraulic lifting on the manufacturing vessel top dish for easy product recovery.

- PLC-based operations with automation, recipe administration, and visualization.

- Vacuum line for sanitation purposes.

- Capacity ranges from 20 kgs to 5000 kgs.

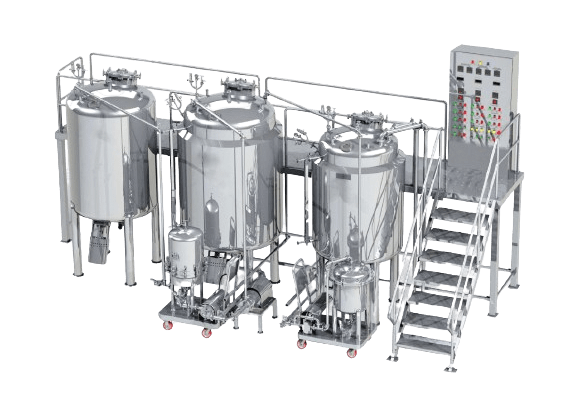

Liquid Oral Manufacturing Plant

Application:

- Syrups

- Oral Liquids

- Suspensions

Concept: The Liquid Oral Plant is designed for the production of syrups, oral liquids, and suspensions. It involves a three-tank process comprising sugar melting, manufacturing, and storage vessels. Stirrers and impellers of various types ensure efficient mixing, while heating jackets and homogenizers maintain product quality.

Salient Features:

- Three-tank process with options for mounting on legs or lugs.

- High-speed stirrers, paddle-type slow-speed stirrers, and anchor-type stirrers for different viscosities.

- Heating jackets or limpets for steam heating, all vessels insulated.

- Electro-polished interconnecting pipelines and TC fittings for easy cleaning.

- Complete the untouched process with the auto transfer of products and ingredients.

- Built-in CIP system for vessel cleaning.

- Load cell-level indicators integrated for precise monitoring.

- Fully automated PLC-based operations with minimal manual handling.

Conclusion

In conclusion, Chemiplant Engineering’s Cream & Ointment Manufacturing Plant and Liquid Oral Manufacturing Plant exemplify the company’s dedication to innovation, efficiency, and quality. With their advanced features, precise control systems, and adherence to regulatory standards, these plants offer pharmaceutical and cosmetic manufacturers the tools they need to produce high-quality products consistently. By investing in these state-of-the-art manufacturing facilities, companies can optimize their production processes, enhance product quality, and meet the evolving demands of the industry.