Various Features of Octagonal Blender Machines

Introduction

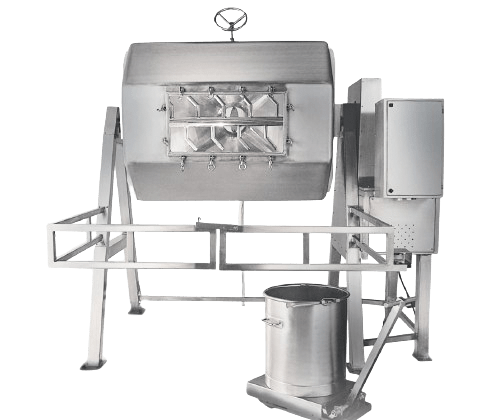

In industries ranging from pharmaceuticals to food processing, achieving precise mixing and blending is paramount for ensuring product quality. Octagonal blender machines stand as indispensable assets in these settings. With their distinct design and multifunctional features, these machines play a vital role in maintaining the consistency and excellence of blended products, particularly of dry granules. Let’s explore the varied features of octagonal blender machines and understand their significance in industrial operations.

Key Features of Octagonal Blender Machines:

- Enhanced Blending Action: Octagonal blenders are widely used in API manufacturing due to their irregular shape, which facilitates higher blending actions in shorter times. This results in efficient and thorough mixing of ingredients.

- Low Power Consumption: These machines are engineered for efficiency, with low power consumption. This not only reduces operational costs but also contributes to sustainable manufacturing practices.

- Hygienic Design: Octagonal blender machines feature a hygienic design with smooth interiors, ensuring compliance with CGMP (Current Good Manufacturing Practices) standards. This facilitates easy cleaning and sanitation, crucial for industries requiring strict hygiene protocols.

- Convenient Charging and Discharging: Charging and discharging of materials are streamlined processes with octagonal blender machines. They are equipped with butterfly valves that allow for manual or pneumatic operation, enhancing convenience and efficiency in material handling.

- Bin Charging System: Octagonal blenders come equipped with a bin charging system, complete with a trolley for easy transportation of materials. This feature enhances operational efficiency and simplifies the loading process.

- Optimal Working Volumes: These machines offer working volumes of up to 70% of total volumes, maximizing efficiency while ensuring proper blending of ingredients. This flexibility allows for versatile usage across a range of batch sizes.

- Suitable for Dry Mixing: Octagonal blender machines are specifically designed for dry mixing of products in granule form, ensuring thorough blending and uniform distribution of ingredients.

- Easy Loading, Unloading, and Cleaning: Octagonal blenders feature user-friendly designs that make the loading and unloading of materials quick and convenient. Additionally, their simple design requires minimum maintenance, further streamlining operations.

- High-Quality Construction: All contact parts of Chemiplant’s octagonal blender machines are made of high-quality stainless steel (SS304, SS316, or SS316L), ensuring durability and compliance with industry standards.

- Safety Measures: The general structure and safety guards of octagonal blender machines are constructed from mild steel or stainless steel, ensuring operator safety. Maximum care has been taken to ensure the safe operation of the unit.

By incorporating these advanced features, octagonal blender machines offer unparalleled performance and reliability in industrial blending operations. From pharmaceutical formulations to food processing and beyond, these machines play a crucial role in maintaining product quality and consistency.

Conclusion

In conclusion, the innovative features of octagonal blender machines, such as those offered by Chemiplant Engineering, revolutionize industrial blending processes. With their efficient blending action, low power consumption, and hygienic design, these machines ensure the highest standards of product quality and consistency. Manufacturers across various industries can rely on Chemiplant Engineering’s octagonal blender machines to streamline their blending operations and achieve superior results.