Importance Of Bin Blenders In The Chemical Industry

In pharmaceuticals and chemical manufacturing, precision, efficiency, and safety are paramount. One of the critical pieces of equipment that helps meet these demands is the bin blender. Designed for blending dry powders used in tablet and capsule production, bin blenders are essential for achieving uniformity and consistency in the final product.

Bin blenders are not just about mixing powders; they play a crucial role in ensuring product quality, preventing cross-contamination, and optimizing production processes. Let’s explore the various applications and features of bin blenders that make them indispensable in the chemical industry.

Efficient Design

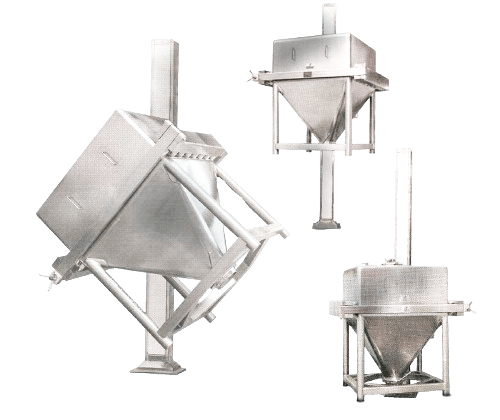

Bin blenders are highly efficient blending containers due to their irregular shape, which promotes better blending and reduces blending times. Bin blenders are equipped with closed containers, preventing exposure to external elements and ensuring product integrity. This is particularly important in industries where product safety is a top priority.

Blending Dry Powders

Bin blenders are specifically designed for blending dry powders used in pharmaceuticals, chemicals, and other industries. The blending process ensures uniform distribution of ingredients, essential for producing high-quality tablets and capsules.

Mixing

In pharmaceutical manufacturing, lubricants are often added to the blend to improve the flow properties of the powder mixture. Bin blenders can effectively mix these lubricants to achieve the desired consistency.

Versatility

Bin blenders are designed with versatility in mind. They consist of pillars, a rotary cage, a hydraulic lifting mechanism, a locking arrangement, a drive arrangement, a breaking system for perfect positioning of the bin, safety sensors, and a PLC control. This allows for easy interchangeability of bins for processing different batch volumes.

Maximum Total Volume

Bin blenders can handle a maximum total volume of up to 3000 liters, making them suitable for large-scale production. The working volume of bin blenders can reach up to 60% of the total volume, ensuring optimal use of the equipment and efficient blending of materials.

Conclusion

Bin blenders are indispensable tools in the pharmaceutical and chemical industries, playing a crucial role in ensuring product quality, safety, and efficiency. Their efficient design, versatility, and ability to blend dry powders uniformly make them essential for achieving consistent and high-quality tablet and capsule production. With their capacity to handle large volumes and prevent cross-contamination, bin blenders are a cornerstone of modern manufacturing processes in these industries. Investing in bin blenders is not just about acquiring equipment; it’s about investing in the reliability and excellence of your production processes.