Understanding the Working Principle of a Conical Mixer Dryer

In the ever-evolving landscape of industrial manufacturing, Chemiplant Engineering Company stands tall as a beacon of innovation and quality. With a journey spanning four decades under the visionary leadership of Mr. Ved Kalra, the company has continually expanded its horizons, enriching its arsenal with new and innovative process equipment. Among its stellar offerings, the Mixer-Dryer emerges as a versatile solution, finding applications across a myriad of industries. Let’s delve deeper into the working principle of the Conical Mixer Dryer and unravel its significance in modern manufacturing processes.

Application Spectrum: Chemiplant’s Mixer-Dryer finds extensive utility in an array of industries, including chemicals, pharmaceuticals, food, confectionery, cement, detergents, chocolates, electronics, and automobiles. Its versatility extends to operations under atmospheric, pressure, or vacuum conditions.

Applications

- Polymeric Reaction

- Reactions under a blanket of inert gas

- Extraction from plants & herbs

- Decaffeination of coffee

- Alkalyzing of cocoa

- Removal of solvents with high boiling points from powders

- Preparation & de-aeration of pastes and creams

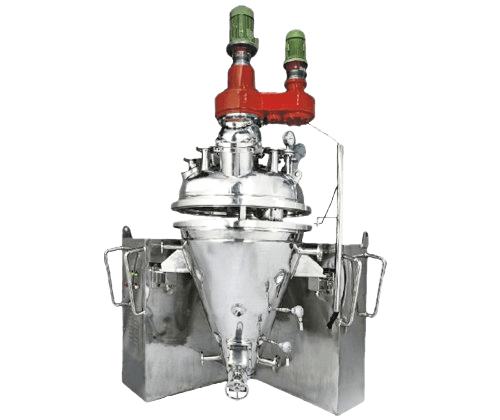

Product Description: The Conical Mixer-Dryer comprises a conical chamber with an orbiting arm and a rotating screw element. This unique design facilitates efficient mixing and higher heat transfer coefficients, resulting in reduced drying times. The discharge of the product occurs through the bottom of the cone, ensuring seamless operation.

Advantages of Conical Mixer-Dryer

- Efficient mixing action and high heat transfer area due to the combined action of the screw and revolving arm.

- Versatility in performing various processes such as mixing, drying, homogenizing, de-aeration, extraction, and reactions.

- Simple and fast loading & discharge of product.

- Compact design requiring low floor space compared to horizontal dryers.

- Suitable for heat-sensitive products due to low product temperature.

- Energy-efficient with low power consumption.

- Environmental and operator safety ensured through totally enclosed operation.

- Large working capacities ranging up to 30KL.

Materials: Standard models are constructed from various grades of Stainless Steel such as SS316/SS316L and SS304/SS304L. Exotic metals like Hastelloy, Monel, Inconel, etc., can also be supplied based on specific requirements.

Pilot Mixer & Dryer: For pilot plants and small-scale productions, Chemiplant offers the SA-Pilot Dry Mixer, a mobile and compact solution equipped with necessary instruments, PLC, and HMI. With batch capacities ranging from 30L to 165L, it facilitates easy scale-up and operations.

Conclusion

In conclusion, the Conical Mixer Dryer epitomizes Chemiplant Engineering Company’s commitment to delivering efficient and versatile process equipment. Its unique design, coupled with advanced features and materials, ensures seamless operation across various industries. By understanding the working principle of this equipment, manufacturers can harness its capabilities to optimize production processes, enhance product quality, and achieve greater efficiency in today’s competitive market landscape.