Rotary Vacuum Paddle Dryer Manufacturers in India

Rotary Vacuum Paddle Dryers (RVPDs) have emerged as essential equipment in various industries for their efficiency in drying heat-sensitive materials while maintaining product quality. As industries in India strive for innovation and optimization, the demand for reliable RVPD manufacturers has surged. In this blog, we delve into the significance of RVPDs, their key features, advantages over conventional drying methods, factors to consider when selecting manufacturers, and how Chemiplant Engineering Company are among the top RVPD manufacturers in India.

Introduction to Rotary Vacuum Paddle Dryers (RVPDs)

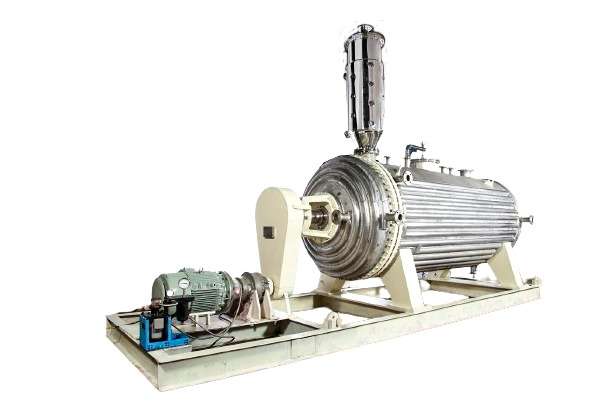

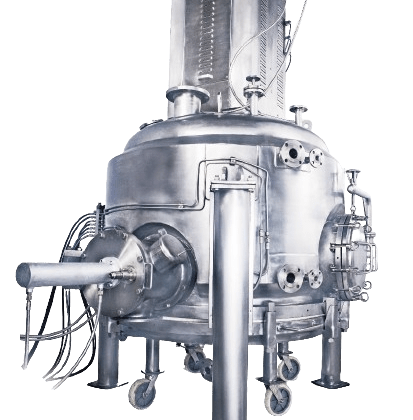

RVPDs are specialized drying equipment used to remove moisture from materials in a controlled environment. They consist of a horizontal cylindrical shell with a hollow shaft and specially designed paddles that promote efficient mixing and drying.

- Chemical Industry

In the chemical industry, RVPDs play a crucial role in drying chemical powders, granules, and slurries. They enable precise control over temperature and pressure, ensuring the preservation of product integrity and quality.

- Pharmaceutical Industry

Pharmaceutical manufacturers rely on RVPDs for drying sensitive active pharmaceutical ingredients (APIs), herbal extracts, and intermediates. The gentle drying process prevents the degradation of heat-sensitive compounds, maintaining the potency of pharmaceutical products.

- Food Industry

In the food industry, RVPDs are used for drying various food products such as fruits, vegetables, and dairy products. Their ability to maintain product color, flavor, and nutritional value makes them indispensable for food processing applications.

Key Features of Rotary Vacuum Paddle Dryers

- Design and Construction

RVPDs are typically constructed with stainless steel or other corrosion-resistant materials to withstand harsh operating conditions. They feature a robust design with vacuum seals to prevent air ingress and ensure efficient moisture removal.

- Operating Principle

The operating principle of RVPDs involves the rotation of the cylindrical shell and paddles, creating a tumbling motion that exposes the material to heat and vacuum conditions. This promotes uniform drying and prevents agglomeration of the dried product.

Advantages of RVPDs over Conventional Drying Methods

RVPDs offer several advantages over conventional drying methods, including:

- Faster drying times

- Lower operating costs

- Reduced risk of product contamination

- Preservation of product quality and integrity

- Flexibility to handle a wide range of materials

Factors to Consider When Choosing RVPD Manufacturers

When selecting RVPD manufacturers in India, several factors should be considered to ensure the procurement of high-quality equipment:

- Reputation and Experience

Choose manufacturers with a proven track record and extensive experience in designing and manufacturing RVPDs. A reputable manufacturer will have a portfolio of successful installations and satisfied customers.

- Quality of Equipment

Evaluate the quality of equipment offered by manufacturers, including materials of construction, design features, and compliance with industry standards. High-quality RVPDs ensure reliable performance and long-term durability.

- Customization Options

Look for manufacturers that offer customization options to tailor RVPDs to specific process requirements. Customized equipment can enhance productivity and efficiency by optimizing drying parameters.

Top Rotary Vacuum Paddle Dryer Manufacturers in India

Chemiplant Engineering Company shines as a top-tier manufacturer of Rotary Vacuum Paddle Dryers (RVPDs) in India, renowned for its innovative designs and superior quality. With a steadfast focus on customer satisfaction and technical excellence, the company leads the industry by continuously pushing the boundaries of drying technology.

Each RVPD undergoes rigorous quality control measures, ensuring impeccable performance and durability. The Company’s commitment to customization allows for tailored drying solutions that optimize efficiency and productivity for its diverse clientele. Upholding transparency and open communication, the company prioritizes exceeding customer expectations at every stage.

With a clientele exceeding 240 domestic and 14 international clients, Chemiplant Engineering’s reputation stands as a testament to its unwavering dedication to excellence and innovation in the drying equipment industry.

Conclusion

Rotary Vacuum Paddle Dryers (RVPDs) have revolutionized the drying process in various industries by offering efficient, reliable, and high-quality drying solutions. When choosing RVPD manufacturers, it is essential to prioritize reputation, quality, and customization options to ensure optimal performance and long-term reliability.