Applications and Benefits of a Powder Conveying System.

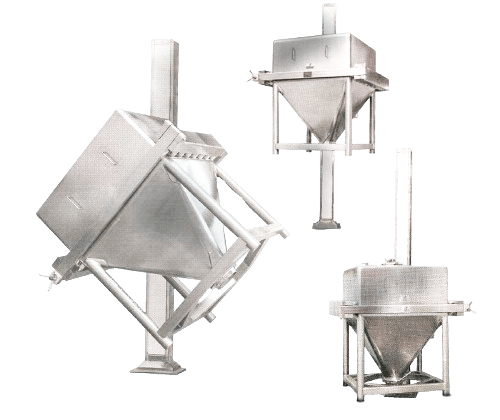

Powder conveying systems are vital for efficiently transporting powdered or granular materials in various industries like food and beverage, pharmaceuticals, chemicals, plastics, mining, cosmetics, and agriculture. These systems offer benefits such as improved efficiency, precise dosing, enhanced safety by reducing spillage and dust exposure, cost-effectiveness through labor savings and reduced wastage, flexibility to handle different materials and production needs, easy integration with automation, and environmental advantages like reduced dust emissions and better workplace cleanliness.

Powder Conveying systems has become one of the most economical and effective methods of transfer of material. In a granulation line, all the individual process equipment like Granulators, Fluid Bed Driers Processors, Milling, and Sifting machines, and most importantly Blenders, need to be charged, discharged, and subsequently conveyed to the successive machines in line.

Powder conveying systems are truly versatile, able to handle a wide range of dry bulk materials across numerous sectors. Their core function is to reliably transfer these materials between different pieces of processing equipment within a production line. Let’s take a closer look at some key industrial applications:

1.Pharmaceutical Manufacturing:

Precision and cleanliness are critical in pharma production. Powder conveying systems play an important role by gently transferring materials like:

- Active drug ingredients

- Excipients

- Granular and powdered formulations

They convey these sensitive materials between equipment like granulators, coaters, dryers, mills, blenders, and tableting machines. The enclosed transfer minimizes dust exposure and contamination risks.

2.Food Production:

Maintaining product integrity is essential in food manufacturing. Conveying systems handle a variety of dry ingredients like:

- Grains and seeds

- Powdered mixes and blends

- Seasoning powders

- Sugar and salt

They transfer these materials between processes like milling, mixing, coating, drying, and packaging – all while preventing outside contamination.

2.Chemical Processing:

Chemical Processing For hazardous or sensitive chemical powders and granules, these systems provide a safe, contained transfer solution. Common applications include conveying:

- Plastic pellets and resins

- Pigments and dyes

- Catalyst powders

- Proppants for fracking

Their ability to gently convey materials helps preserve product quality.

Here are some key benefits of powder transfer systems:

Enclosed, Dust-Free Transfer One of the biggest advantages is that powder transfer systems provide an enclosed, dust-tight conveying solution. The materials being transferred remain fully contained within the system, preventing any product loss or dust exposure. This is especially important when handling hazardous, potent, or sensitive materials like pharmaceuticals or certain chemicals.

Gentle Product Handling These systems are designed to convey bulk solids gently, minimizing any degradation or attrition of the material. The conveying air stream handles the product carefully, preserving characteristics like particle size and integrity. This makes them ideal for fragile or friable materials.

Contamination Prevention With an enclosed design, the risk of outside contamination from the surrounding environment is very low. The product stream is fully sealed off from potential contaminants like dust, moisture, or other foreign materials that could negatively impact quality.

Easy Cleaning/Purging Powder conveying systems feature smooth interior surfaces that allow full purging between product transfers. This makes cleaning efficient and simplifies product changeovers, reducing downtime. Some systems even incorporate clean-in-place (CIP) capabilities.

Precision Control Advanced control systems give operators the ability to tightly control and monitor product transfer rates. This level of precision ensures accurate feed rates to downstream equipment for optimal process control.

Compact Design Compared to other conveying methods like screw augers or bucket elevators, these systems have a relatively small footprint. Their simple design with flexible routing makes them easy to integrate into existing process lines.

Conclusion:

Powder conveying systems have become a cornerstone of efficient and safe material handling across a multitude of industries. Their ability to precisely transfer a wide range of dry, bulk materials while minimizing dust and product degradation makes them an invaluable asset. From the delicate world of pharmaceuticals to the large-scale production of food and chemicals, these systems offer a compelling blend of benefits.

If you’re looking to optimize your material handling processes, improve product quality, and ensure a cleaner work environment, then a powder conveying system might be the perfect solution. With their versatility, efficiency, and focus on safety, these systems are poised to continue revolutionizing powder and granular material transfer for years to come.