Exploring the Key Roles of ANFD in the Pharmaceutical Field

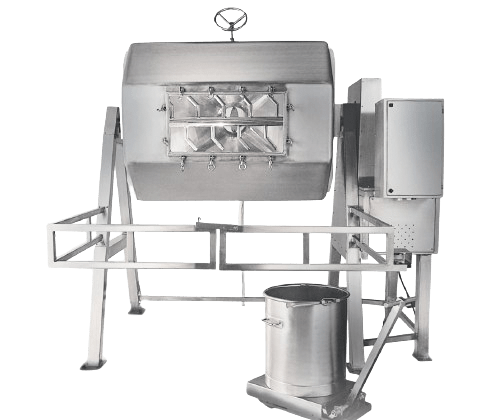

Chemiplants ANFDs are used for solid-liquid separations under pressure & or vacuum. The closed operation ensures consistent product quality, simple validation, and also a required operational safety.

The advanced combination of agitation & hydraulics used in these filters/dryers make them versatile and user-friendly. The resulting wet cakes can be re-slurried and washed thoroughly with water or solvents unlike manual Nutsche Filters and Centrifuges. The discharge of the cake is automatic. If the process demands filtration in a hot or chilled condition the same can be achieved. Finally drying operations can also be conducted within the same equipment.

Chemiplant filters & dryers are successfully installed in the Inorganic and Organic Chemical, Fine Chemical, and most importantly in the Pharmaceutical Industries. These filter dryers can be customized for various processes such as Crystallization, Filtration, Decoloration, Washing & Drying with a variety of options namely different shaft seals, bottom enclosure mechanisms, CIP, etc. The size or selection of a filter/filter-dryer is purely determined by the volume of cake to be handled in a batch & also the nature of the material to be filtered.

Key Roles of ANFD in the Pharmaceutical Field

- Quick Opening Detachable Bottom: The quick-opening detachable bottom allows for easy access to the interior of the equipment for cleaning, maintenance, and batch changes, ensuring minimal downtime and maximum efficiency.

- CIP Arrangement: The Clean-in-Place (CIP) arrangement facilitates automated cleaning of the equipment’s interior surfaces, ensuring optimal hygiene and compliance with pharmaceutical standards.

- Steam Sterilizable: The ANFDs are designed to be steam sterilizable, ensuring that the equipment meets the strict hygiene standards required for pharmaceutical production.

- Online Sampling Valve: The online sampling valve allows for convenient and representative sampling of the process stream, enabling real-time monitoring of the process and ensuring product quality and consistency.

- Sintered Metal Filter or Filter Media: The ANFDs can be equipped with a sintered metal filter or other suitable filter media, ensuring efficient and reliable solid-liquid separation for pharmaceutical applications.

- Agitator with Mechanical Seal: The advanced combination of agitation and hydraulics, including an agitator with a mechanical seal, ensures thorough mixing and efficient filtration, enhancing process efficiency and product quality.

- Comply with GMP Standards: The ANFDs are designed and manufactured to comply with Good Manufacturing Practice (GMP) standards, ensuring that they meet the highest quality and hygiene standards required in pharmaceutical production.

- Metal to Metal Sealing Discharge Valve: The metal-to-metal sealing discharge valve ensures reliable and leak-free operation, enhancing operational safety and ensuring product containment during the discharge process.

Conclusion

In conclusion, Chemiplant’s ANFDs are vital in the pharmaceutical industry, offering solid-liquid separation under pressure or vacuum. Their closed operation ensures consistent product quality and operational safety. These filter/dryers can handle various processes like crystallization, filtration, and drying, and are customizable for different needs. Key features include quick-opening detachable bottoms, CIP arrangements, steam sterilizability, and compliance with GMP standards, making them versatile and user-friendly. They play a crucial role in ensuring efficient and reliable pharmaceutical production processes.