How to Choose the Right Bin Blender for Your Food Processing Needs

In the realm of food processing, where precision, consistency, and adherence to strict quality standards are paramount, selecting the appropriate equipment is essential. Bin Blenders, with their versatile capabilities, play a crucial role in facilitating efficient blending processes across various stages of food production. Let’s explore further how Bin Blenders contribute to enhancing food processing operations.

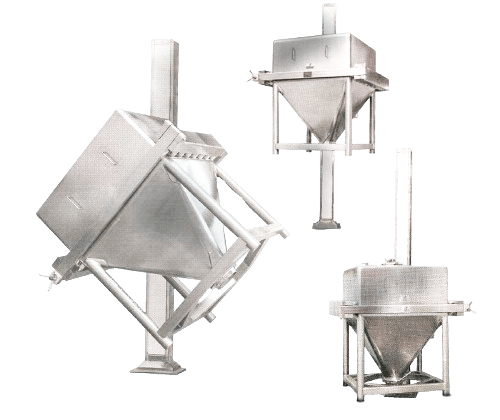

Salient Features

1. Highly Efficient Blending Containers: Bin Blenders are renowned for their irregular shape, which promotes optimal blending efficiency. This unique design ensures thorough mixing of food powders, resulting in uniformity and consistency in the final product.

2. Versatility: Equipped with pillars, rotary cage, hydraulic lifting mechanism, locking arrangement, drive arrangement, breaking system, safety sensors, and PLC control, Bin Blenders offer unmatched versatility in blending various food ingredients and formulations.

3. Easy Interchangeability of Bins: Designed for seamless interchangeability of bins, these blenders facilitate swift and hassle-free transitions between different batch volumes, thereby enhancing operational flexibility and productivity.

Applications in Food Processing

- Mixing Dry Powders: Bin Blenders are extensively utilized for mixing dry powders such as flour, spices, seasonings, and powdered additives. This ensures homogeneous distribution of ingredients, contributing to the consistent flavor profile and quality of food products.

- Mixing Lubricants: In food manufacturing processes, lubricants are often used to facilitate equipment operation and prevent friction-related issues. Bin Blenders ensure thorough blending of lubricants with dry ingredients, ensuring uniform dispersion and enhancing processing efficiency.

- Preventing Cross-Contamination: With their enclosed blending environment, Bin Blenders help prevent cross-contamination between batches, ensuring the integrity and safety of food products. This is particularly crucial in facilities producing allergen-sensitive or specialty dietary products.

- Tumble Blending: The tumbling action of Bin Blenders promotes gentle yet effective blending of food powders, preventing clumping and ensuring consistent texture and flavor distribution. This is essential for achieving desired product characteristics in applications such as baking mixes, powdered beverages, and seasoning blends.

- Closed Container Blending: Bin Blenders enable blending within closed containers, maintaining product integrity and minimizing exposure to external contaminants. This is particularly advantageous for sensitive ingredients or formulations requiring precise handling and protection from environmental factors.

Conclusion

In the dynamic landscape of food processing, Bin Blenders emerge as indispensable assets, offering unmatched blending efficiency, versatility, and adherence to stringent quality and safety standards. With their innovative design and diverse applications, Bin Blenders play a pivotal role in enhancing the efficiency, consistency, and quality of food processing operations, thereby contributing to the delivery of superior food products to consumers worldwide.