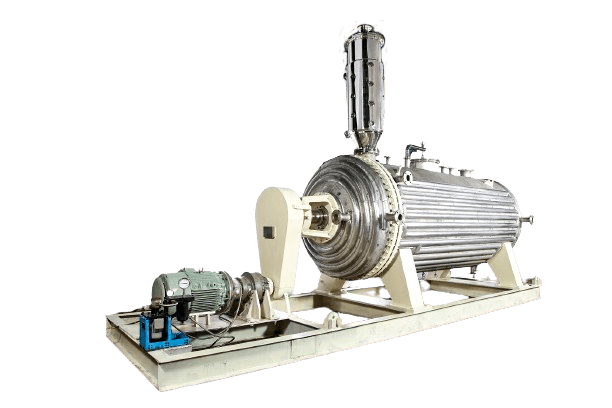

Chemiplant’s Rotary Vacuum Paddle Dryers serve as essential tools for transforming wet cakes or solutions into dry powders efficiently. These dryers typically operate under vacuum conditions and function as batch operations. Featuring a fixed cylindrical shell with a centrally located rotating agitator, these dryers boast a hollow rotating shaft heated by hot water or steam circulation. Mechanical seals are incorporated on both the utility side and the vacuum side to ensure optimal performance.

With a large heat transfer area facilitated by the heated shaft and paddles, these dryers achieve maximum heat transfer coefficients. The drive mechanism comprises a reduction gearbox with a chain sprocket system coupled to the drive motor, providing reliable operation. Mounted on a skid, the entire assembly, along with the dryer chamber, minimizes foundation costs and reduces maintenance expenses.

Materials of construction primarily include Stainless Steel AISI 316, with the option for special alloys such as C22 and C276 available upon request. Offering a comprehensive solution, Chemiplant’s Rotary Vacuum Paddle Dryers enable multiple operations within a single unit. Processes like mixing, liquid addition, evaporative concentration, reaction, drying, and cooling are seamlessly carried out without the need for intermediate storage, transportation, or cleaning.

Advantages of Paddle Dryer:

- Ensures safety for operators, the environment, and the product.

- Achieves high vacuum levels with minimal final moisture content in the product.

- Maintains uniformity and homogeneity throughout the drying batch.

- Reduces power consumption, enhancing operational efficiency.

- Facilitates ease of washing for batch changeovers due to effective Clean-In-Place (CIP) systems.

- Enables solvent recovery, enhancing overall process sustainability.

Turn-Key Supply System – Cantilever Dryer:

Chemiplant offers a comprehensive range of accessories tailored for the Rotary Vacuum Paddle Dryer, including necessary fittings designed to meet diverse process requirements:

- Heating and cooling assembly for the jacket/limpet, comprising a hot water tank, circulation pump, heating/cooling coil, and necessary control valves.

- Dust collector system effectively captures valuable product carried away with vapors in a filter bag, utilizing reverse flow of N2 air in a pulsation circuit to redirect the product back into the dryer.

- Vacuum pump ensures optimal vacuum conditions within the dryer chamber.

- Necessary piping and valves are available upon request to streamline the installation process.

- Control panel with PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) system, equipped with VFD (Variable Frequency Drive), timers, contactors, relays, and temperature indicators/controllers, enabling centralized supervision and process management, ensuring reproducibility and control.