Application of Octagonal Blenders in the manufacturing processes of Chemicals and Active Pharmaceutical Ingredients (APIs)

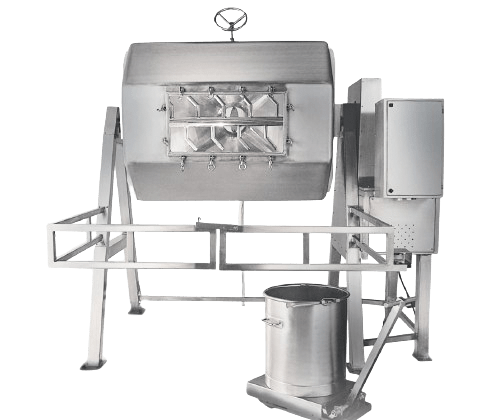

The octagonal blender stands out as a cornerstone in the manufacturing processes of chemicals and active pharmaceutical ingredients (APIs), offering a blend of efficiency and versatility. This blending machine is designed for the homogeneous mixing and lubrication of dry granules, ensuring a seamless production process.

Applications:

1. Blending: The octagonal blender is adept at gently blending dry powders and granules, ensuring a uniform mix without compromising the integrity of the ingredients.

2. Variable Speed Operation: The blending process occurs at low to medium speeds, offering flexibility to match the process requirements, thereby ensuring optimal blending outcomes.

3. Pharmaceutical, Food, Chemical, and Cosmetic Industries: The octagonal blender finds extensive use across industries, including pharmaceuticals, food processing, chemicals, and cosmetics, due to its ability to deliver consistent blending results.

4. Ideal for APIs: The blender’s unique octagonal shape enhances blending action, making it particularly suitable for APIs, where precise and thorough blending is crucial. This design ensures a higher blending efficiency in shorter durations, thereby increasing productivity.

5. Energy Efficiency: The octagonal blender is known for its low power consumption, making it an environmentally friendly and cost-effective choice for manufacturers.

6. Hygienic Design: With a smooth interior designed for CGMP cleaning, the blender ensures the highest standards of hygiene and product safety, crucial in industries where cleanliness is paramount.

7. Easy Charging and Discharging: The blender features a convenient charging and discharging system, with options for manual or pneumatic operation, providing ease of use and efficiency in the manufacturing process.

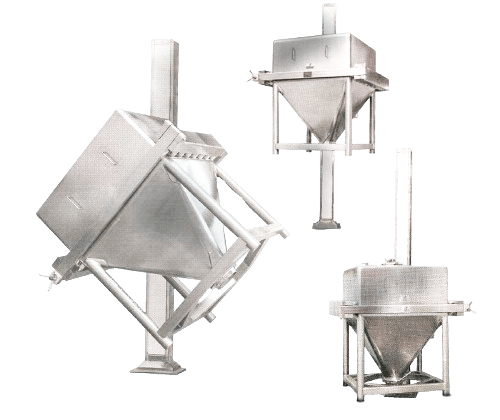

8. Bin Charging System: The blender is equipped with a bin charging system with trolley, facilitating the easy and safe transfer of materials, enhancing operational efficiency.

9. Optimal Working Volumes: The blender allows for working volumes of up to 70% of the total volume, ensuring efficient blending even with varying batch sizes.

Conclusion:

In conclusion, the octagonal blender is a vital tool in the manufacturing processes of chemicals and APIs, offering a range of benefits including efficient blending, energy efficiency, hygienic design, and ease of operation. Its versatility makes it a valuable asset across industries, providing manufacturers with the means to achieve consistent and high-quality blending results.