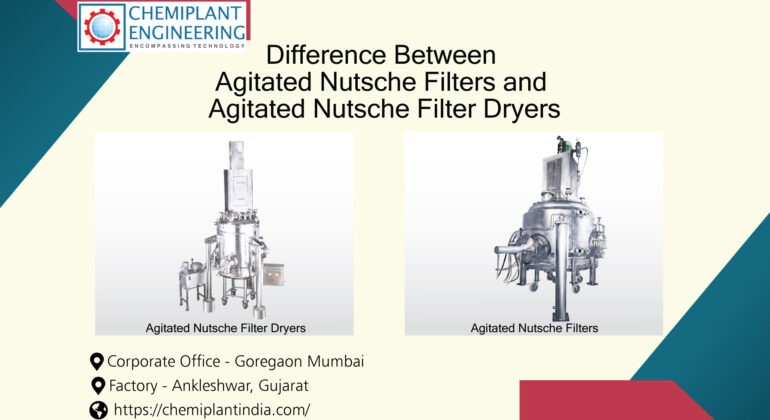

Understanding the Difference Between Nutsche Filters and Nutsche Filter Dryers in the Pharmaceutical Industry

Introduction

Chemiplant Agitated Nutsche Filters (ANF) and Agitated Nutsche Filter & Dryer (ANFD) are used for solid-liquid separations under pressure & or vacuum. The closed operation ensures consistent product quality, simple validation, and also required operational safety.

The advanced combination of agitation & hydraulics used in these filter/dryers make them versatile and user-friendly. The resulting wet cakes can be re-slurried and washed thoroughly with water or solvents unlike manual nutsche filters and centrifuges. The discharge of the cake is automatic. If the process demands filtration in a hot or chilled condition the same can be achieved. Finally drying operations can also be conducted within the same equipment.

Let’s delve into the disparities between Agitated Nutsche filters and Agitated Nutsche filter dryers to understand their respective advantages and applications within the pharmaceutical sector.

1. Functionality difference between Nutsche Filters and Nutsche Filter Dryers:

- Nutsche Filters: As the name implies, Nutsche filters are primarily designed for solid-liquid separation through filtration. They excel at removing solids from liquid suspensions, enabling the recovery of valuable products or the purification of solutions.

- Nutsche Filter Dryers: Building upon the filtration capabilities of Nutsche filters, Nutsche filter dryers integrate an additional drying function within the same vessel. This combination allows for seamless transitioning from filtration to drying, streamlining the overall process and reducing the need for separate equipment.

2. Process Integration:

- Nutsche Filters: Typically employed as standalone units, Nutsche filters are dedicated to the filtration step, requiring additional downstream processing for drying or further treatment of the filtered solids.

- Nutsche Filter Dryers: By incorporating drying capabilities, Nutsche filter dryers consolidate multiple process steps into a single unit. This integration not only saves valuable floor space but also minimizes product transfer and potential contamination risks associated with manual handling.

3. Operational Efficiency:

- Nutsche Filters: While highly efficient in their filtration function, Nutsche filters necessitate additional time and resources for transferring the filtered solids to separate drying equipment, potentially increasing overall processing times.

- Nutsche Filter Dryers: The combined filtration and drying capabilities of Nutsche filter dryers result in enhanced operational efficiency. The seamless transition from filtration to drying within the same vessel reduces processing times, leading to increased throughput and productivity.

4. Flexibility and Versatility:

- Nutsche Filters: Designed primarily for filtration, Nutsche filters offer limited versatility in terms of additional process steps or specialized treatments.

- Nutsche Filter Dryers: With their integrated drying function, Nutsche filter dryers exhibit greater versatility. They can accommodate various drying techniques, such as vacuum drying, heated jacket drying, or agitated drying, catering to the specific requirements of different pharmaceutical products.

5. Product Quality and Safety – Nutsche Filters and Nutsche Filter Dryers:

Both Nutsche filters and Nutsche filter dryers prioritize product quality and safety, adhering to stringent pharmaceutical industry standards. However, the reduced product handling and enclosed processing environment of Nutsche filter dryers further minimize the risk of contamination and enhance product integrity.

Conclusion

In conclusion, while both Nutsche filters and Nutsche filter dryers are indispensable for solid-liquid separation in the pharmaceutical industry, their differences in functionality, process efficiency, product quality, and versatility make each suitable for specific applications. Pharmaceutical manufacturers must carefully evaluate their process requirements and objectives to determine the most appropriate equipment choice that aligns with their production needs and quality standards.

For more information on Chemiplant Agitated Nutsche Filters (ANF) and Chemiplant Agitated Nutsche Filter & Dryer (ANFD), visit Chemiplant Engineering Solutions.

FAQs

ANF (Agitated Nutsche Filters) primarily perform solid-liquid separation through filtration, while ANFDs (Agitated Nutsche Filter Dryers) integrate drying capabilities alongside filtration.

When selecting equipment, it’s important to consider various factors such as:

– Capacity: Ensure the equipment can handle the required volume of materials efficiently without overloading or underutilization.

– Integration: Look for equipment that seamlessly integrates with existing processes and workflows to minimize disruptions and enhance overall efficiency.

– Quality Standards: Prioritize equipment that meets or exceeds industry regulations and quality standards, such as cGMP (current Good Manufacturing Practice), to ensure product safety and compliance.

Yes, ANFDs offer versatility in drying techniques including vacuum drying, heated jacket

ANFDs streamline the production process by combining filtration and drying functions in a single unit, reducing processing times, minimizing product handling, and enhancing overall efficiency compared to standalone ANFs.

Our equipment boasts advanced features like agitation, hydraulics, and integrated drying capabilities, providing versatility and user-friendliness for various processes.