Exploring the Different Applications of Ribbon Blenders Across Industries

In the domain of manufacturing, the significance of efficient mixing and blending processes cannot be overstated. This is where ribbon blenders, versatile workhorses of the industry, come into play. Among the pioneering companies in the domain of process equipment, Chemiplant Engineering stands tall, offering top-notch solutions to various sectors. Let’s delve into the myriad applications of ribbon blenders across industries and understand how they contribute to seamless production processes.

Different Applications of Ribbon Blenders:

Mixing Dry Foods: Ribbon blenders find extensive use in the food industry, particularly in mixing dry foods. Whether it’s blending nutraceuticals, protein powder mixes, or dry juice mixes, ribbon blenders ensure homogeneous mixing, maintaining the integrity of the final product.

Mixing Chemicals: In the chemical industry, where precise formulations are paramount, ribbon blenders play a crucial role. They efficiently blend dry powders and granules to create fertilizers, pesticides, and various chemical products, ensuring uniform distribution of ingredients.

Mixing and Coating: Ribbon blenders excel in coating and mixing processes, a necessity in industries where surface treatment of particles is required. Whether it’s coating minor ingredients onto bulk materials or ensuring uniform distribution of additives, ribbon blenders deliver consistent results.

Mixing Pharmaceutical Products: The pharmaceutical industry demands stringent quality control and precise blending of ingredients. Ribbon blenders prove invaluable in mixing pharmaceutical products, ensuring uniform dispersion of active pharmaceutical ingredients (APIs) and excipients.

Mixing Food Products: From blending ingredients for bakery products to mixing seasonings for snacks, ribbon blenders find diverse applications in the food industry. Their ability to handle a wide range of viscosities and densities makes them indispensable for achieving desired product characteristics.

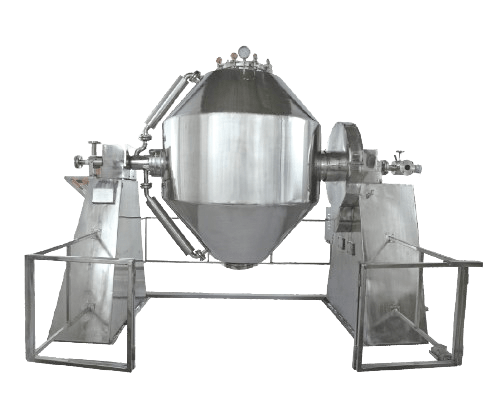

Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

- Full cover on the top side of the container.

- Dustproof top cover with a window provided.

- Safety Guards & Covers made out of SS304 in GMP Model

- Three-phase indication facility.

- Emergency stop provided in panel.

- Digital timer for batch time setting.

- Discharge height must be adjusted if confirm with the order.

- The operating panel provided for the safe operation of Ribbon Blender.

- Centrally located material Discharge valve. (Butterfly / Sliding Valve)

- Ampere meter to indicate load of the motor in ampere.

- Limit switch provided at the top cover for safety purposes.

- Inching push button with a selector switch for inching operation during discharge of material.

- The shape of the container & mixing stirrer gives sufficient continuous movement to the powder/granules, resulting in good quality.

- All contact parts of the Ribbon Blender are made out of SS304/SS316 or SS316 L quality material.

In conclusion, ribbon blenders serve as indispensable assets across various industries, facilitating efficient mixing and blending processes. Chemiplant Engineering, with its commitment to innovation and quality, stands as a leading provider of process equipment, including ribbon blenders. As industries continue to evolve and diversify, the versatility and reliability of ribbon blenders ensure their enduring relevance in modern manufacturing processes.