A Closer Look at the Inner Workings of Conical Mixer and Dryer Machines

In the realm of pharmaceutical and chemical process equipment, Chemiplant Engineering Company stands out as a beacon of innovation and quality. Under the visionary leadership of Mr. Ved Kalra, the company has flourished over four decades, continually adding new and innovative process equipment to its repertoire. Among its offerings are conical mixer and dryer machines, versatile tools that find diverse applications in various industries.

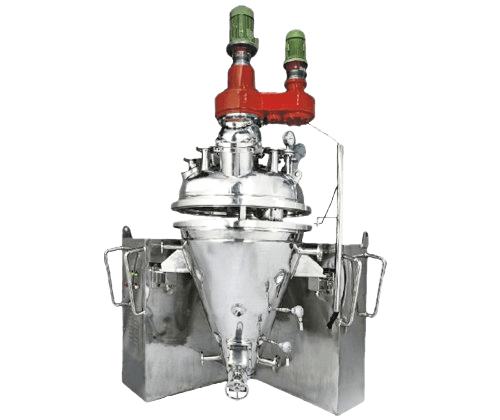

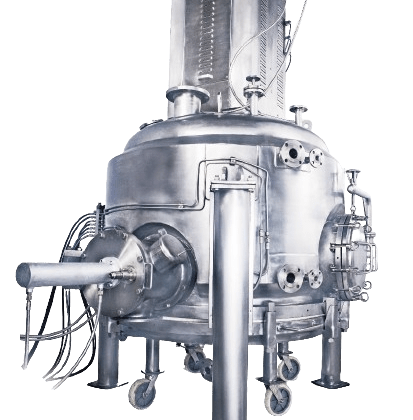

Chemiplant’s Mixer-Dryer is widely used for processing products in a wide spectrum of industries ranging from chemicals, pharmaceuticals, food, confectionery, cement, detergents & soap, chocolates, electronics (additives) & automobiles (brake lining compounds). This broad field of application includes both operations of atmospherics & pressure or vacuum. Chemiplant’s Conical Mixer-Dryer consists of a conical chamber with an orbiting arm and a rotating screw element.

A unique feature of this system is the combination of the upward motion of the product (with the help of a screw) and the secondary transporting movements of the particles along the periphery resulting in a thorough & quick mix along with higher heat transfer coefficients (reduced drying times). The discharge of the product takes place through the bottom of the cone.

Materials:

- Standard models come in various grades of Stainless Steel like SS316/SS316L and SS304/SS304L.

- Exotic Metals such as Hastealloy, Monel, Inconel, etc can also be supplied as per the requirements.

Advantages of Conical Mixer – Dryer:

- Efficient Mixing action and high heat transfer area due to the combined action of the screw and revolving arm (hence faster drying)

- Combination of various processes in a single piece of equipment namely mixing, drying, homogenizing, de-aeration, extraction (herbs) & various reactions (solvent recovery).

- Simple, fast loading & discharge of Product.

- Low floor Space is required compared to other horizontal dryers.

- Low product temperature & most suitable for heat-sensitive products.

- Low power consumption compared to horizontal dryers & hence energy savings.

- Totally enclosed operation ensures environmental & operator safety.

- Large working capacities ranging up to 30KL.

Applications:

Polymeric Reaction:

Conical mixer and dryer machines facilitate polymeric reactions, allowing for the synthesis of polymers with precise control over parameters such as temperature and mixing intensity. These machines ensure thorough blending of polymer precursors, leading to uniform polymerization and the desired product characteristics.

Reactions under a Blanket of Inert Gas:

In industries where reactions must be carried out under an inert atmosphere to prevent oxidation or other undesirable reactions, conical mixer and dryer machines prove invaluable. They provide a sealed environment conducive to conducting reactions under a blanket of inert gas, ensuring product purity and consistency.

Extraction from Plants & Herbs:

Conical mixer and dryer machines are employed in the extraction process of valuable compounds from plants and herbs. By combining gentle mixing with controlled drying, these machines help extract essential oils, flavors, and active ingredients efficiently, preserving their integrity and potency.

Decaffeination of Coffee:

The decaffeination process of coffee beans involves the removal of caffeine while retaining the flavor compounds intact. Conical mixer and dryer machines play a crucial role in this process by facilitating solvent extraction and subsequent drying, ensuring that the decaffeinated coffee retains its aroma and taste.

Alkalizing of Cocoa:

In the chocolate industry, conical mixer and dryer machines are utilized for alkalizing cocoa powder, a process that modifies its flavor and color. These machines ensure thorough mixing of cocoa powder with alkali agents, followed by controlled drying, resulting in cocoa with the desired alkalinity and taste profile.

Removal of Solvents with High Boiling Points from Powders:

Conical mixer and dryer machines are adept at removing solvents with high boiling points from powders, a common requirement in pharmaceutical and chemical processing. Through a combination of gentle mixing and controlled drying, these machines facilitate solvent removal without compromising product quality.

Preparation & De-aeration of Pastes and Creams:

Conical mixer and dryer machines are utilized for the preparation and de-aeration of pastes and creams in the cosmetic and pharmaceutical industries. By subjecting the mixture to controlled agitation and vacuum drying, these machines ensure the removal of air bubbles, resulting in smooth and homogeneous products.

Conclusion

In conclusion, conical mixer and dryer machines exemplify the ingenuity and versatility of Chemiplant Engineering Company’s offerings. From facilitating polymeric reactions to aiding in the extraction of valuable compounds from natural sources, these machines find diverse applications across industries. With their precise control over mixing and drying parameters, conical mixer and dryer machines contribute to the efficient and reliable processing of pharmaceuticals, chemicals, and other products, reflecting Chemiplant Engineering’s commitment to excellence in process equipment manufacturing.