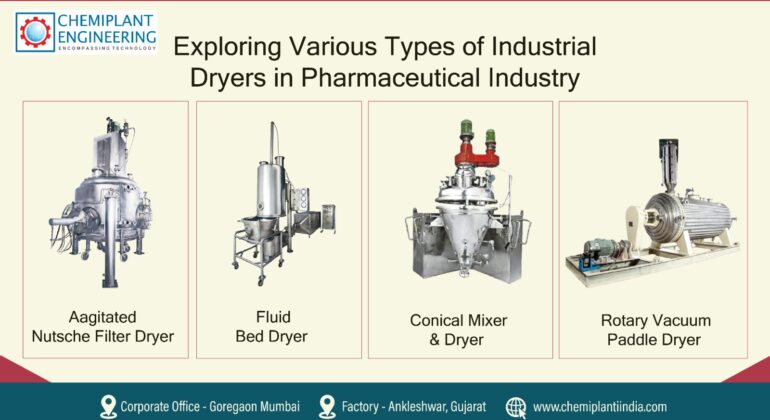

Exploring Various Types of Industrial Dryers in Pharmaceutical Industry

Moisture control is a critical aspect of pharmaceutical manufacturing. Maintaining precise moisture levels within products ensures their stability, potency, and proper formulation. Industrial dryers play a vital role in this process, acting as the workhorses behind countless medications. This blog explores some of the most common industrial dryers used in the pharmaceutical industry, highlighting their strengths, applications, and considerations for selection.

Agitated Nutsche Filter

A mainstay for solid-liquid separation, the nutsche filter features a rotating, agitated vessel with a filter cloth at the bottom. The liquid slurry is fed into the vessel, where solids are collected on the filter cloth as it rotates. The remaining liquid filtrate then passes through.

- Strengths: Simple design, efficient separation, versatility for various slurries.

- Applications: Crystallization processes, API (Active Pharmaceutical Ingredient) isolation, product washing.

- Considerations: Batch process, may require additional drying equipment for complete moisture removal.

Agitated Nutsche Filter Dryer (Chemiplant ANFDs)

Taking the Nutsche Filter concept a step further, the Chemiplant ANFDs offer a closed-loop system with significant advantages:

- Enhanced Performance: Closed operation ensures consistent product quality, simplifies validation processes, and strengthens operational safety.

- Advanced Agitation and Hydraulics: This innovative design makes the ANF and ANFDs highly versatile and user-friendly.

- Thorough Washing: Unlike manual Nutsche Filters and centrifuges, these dryers allow for efficient re-slurring and thorough washing of the wet cake with water or solvents.

- Automated Cake Discharge: For added convenience, cake discharge is automatic.

- Temperature Control: The system can handle filtration in hot or chilled conditions, providing flexibility for diverse processes.

- Multi-Step Processing: The ANFDs offer a complete drying cycle within a single unit, including:

- Charging

- Filtering

- Washing

- Reslurry / Washing

- Cake Smoothing

- Drying/Cooling

- Discharging

Rotary Vacuum Paddle Dryer

The vacuum paddle dryer utilizes a heated, rotating vessel with internal paddles that continuously turn and mix the product. The vacuum environment facilitates rapid moisture evaporation at a lower temperature, minimizing product degradation.

The Chemiplant RVPD takes versatility to another level. This dryer has the ability to carry out multiple operations in a single unit, eliminating the need for intermediate storage, transportation, or cleaning. Here’s a breakdown of its capabilities:

- Multi-Functionality: Processes like mixing, liquid addition, evaporative concentration, reaction, drying, and cooling can all be performed within the RVPD.

- Batch Operation: The RVPD is a batch operation that utilizes a fixed cylindrical shell with a central rotating agitator. The heated shaft and paddles provide a large heat transfer area for efficient drying.

- Vacuum Operation: Mostly operated under vacuum, the RVPD is ideal for drying heat-sensitive materials.

- Skid-Mounted Design: The entire assembly is mounted on a skid, reducing foundation costs and simplifying maintenance.

Fluid Bed Dryer

The fluid bed dryer utilizes a bed of inert particles fluidized by a stream of air. The moist product is introduced into the fluidized bed, and the heated air rapidly removes moisture from the product surface.

- Strengths: Uniform drying, excellent control over drying conditions, continuous operation, good for heat-sensitive materials.

- Applications: Granulation drying, moisture reduction in powders and granules, final product drying

- Considerations: Requires careful control of airflow and temperature to prevent product loss or clumping, may not be suitable for large, dense particles.

Fluid Bed Dryer Explained by Chemiplant:

Chemiplant offers a fluid bed dryer specifically designed for drying wet granulated materials. Here’s a closer look at the process:

- Drying Mechanism: The material is dried through a combination of moisture diffusion from within the granules and forced-air convection.

- Efficient Heat and Mass Transfer: Hot and dehumidified air fluidizes the granulated material, ensuring efficient heat and mass transfer for optimal drying.

- Batch Operation: Similar to the RVPD, the fluid bed dryer is a batch operation that converts moist material to a free-flowing state using a hot air stream.

- Detailed Process Flow: Air drawn from outside is passed through a three-stage filtration system (pre, fine, and HEPA) before being heated by steam coils or electric heaters.

Conical Mixer & Dryer

The conical mixer dryer is a versatile piece of equipment used in the pharmaceutical industry and beyond. Its unique conical shape and internal mixing elements allow for efficient blending and drying of various materials in a single unit. This eliminates the need for separate mixing and drying equipment, streamlining the process and saving valuable space.

Chemiplant’s Mixer-Dryer:

Chemiplant offers a conical mixer dryer specifically designed to excel in diverse applications. Here’s a closer look at its capabilities:

- Broad Applicability: Chemiplant’s Mixer-Dryer finds use in a wide range of industries, including pharmaceuticals, chemicals, food, and more.

- Multi-Functional Operations: This versatile unit can handle both atmospheric and pressure/vacuum operations, making it suitable for a variety of processes.

- Sample Applications: Chemiplant’s Mixer-Dryer tackles various tasks, including polymeric reactions, extractions from plants and herbs, solvent removal from powders, and preparation of pastes and creams.

Choosing the Right Dryer: A Balancing Act

Selecting the optimal industrial dryer for your pharmaceutical application requires careful consideration of several factors:

- Product Characteristics: Is the product heat-sensitive? Does it require gentle drying? Understanding the physical and chemical properties of the product is crucial.

- Desired Drying Rate: How quickly does the product need to be dried? Production throughput and batch sizes also play a role.

- Capacity Requirements: What volume of product needs to be dried per batch or continuously?

- Budgetary Constraints: The initial investment cost and operational expenses of each dryer type should be factored in.

- Regulatory Compliance: The dryer should meet all relevant pharmaceutical industry regulations and Good Manufacturing Practices (GMP) requirements.

Conclusion

Industrial dryers play a vital role in the pharmaceutical manufacturing process, ensuring the quality, stability, and effectiveness of medications. By understanding the various types of dryers available and carefully evaluating your specific needs, you can select the optimal option that delivers efficient drying while safeguarding product integrity. Contact Chemiplant Engineering, to get great deals on premium industrial dryers.

FAQs

Industrial dryers are used to control moisture levels in pharmaceutical products. This ensures the medications remain stable, potent, and properly formulated.

The ANFD has many benefits, including a closed-loop system for consistent quality, advanced mixing for versatility, thorough washing capabilities, automatic cake discharge, temperature control, and the ability to perform multiple steps like filtering and drying in one unit.

The RVPD dries materials in a vacuum, which allows moisture to evaporate at lower temperatures, protecting heat-sensitive products. It also combines multiple processes like mixing and cooling in one machine.

When choosing a dryer, consider the product’s sensitivity to heat, how quickly it needs to be dried, the volume of product to be dried, cost, and regulatory compliance. These factors help ensure you select the right dryer for your needs.

Chemiplant’s Fluid Bed Dryer uses hot, dehumidified air to fluidize and dry granulated materials efficiently. The system includes a thorough air filtration process and heats the air with steam coils or electric heaters to ensure effective drying.