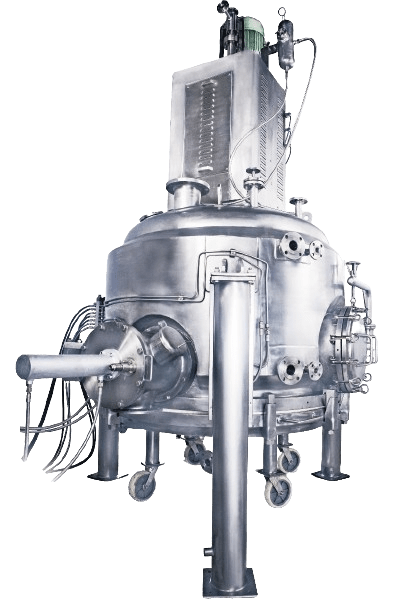

Chemiplant ANF and ANFD are used for solid-liquid separations under pressure & or vacuum. The closed operation ensures consistent product quality, simple validation, and also required operational safety.

The advanced combination of agitation & hydraulics used in these filter/dryers make them versatile and user-friendly. The resulting wet cakes can be re-slurried and washed thoroughly with water or solvents unlike manual nutsche filters and centrifuges. The discharge of the cake is automatic. If the process demands filtration in a hot or chilled condition the same can be achieved.

Finally drying operations can also be conducted within the same equipment.

Materials of construction:

Chemiplant filter/filter dryers are offered in Stainless Steel, Hastealloy, and Special alloy metals. For highly alkaline/acidic products we offer various compatible grades of Lined or Coated fluoro polymer such as Halar, PTFE, PVDF, etc. Typically in such Filter/dryers only the Agitator shaft & blades are supplied with exotic materials

Applications:

- Chemiplant filters & dryers are successfully installed in the Inorganic and Organic Chemical, Fine chemical, and most importantly Pharmaceutical Industries.

- These filter dryers can be customized for various processes such as Crystallization, Filtration, Decoloration, Washing & Drying with a variety of options namely different shaft seals, bottom enclosure mechanisms, CIP, etc.

- The size or selection of a filter/filter-dryer is purely determined by the volume of cake to be handled in a batch & also the nature of the material to be filtered.

The key features of an Agitated Nutsche Dryer:

• Quick opening detachable bottom

• CIP Arrangement

• Steam sterilizable

• Online sampling valve

• Sintered metal filter or filter media

• Agitator with Mechanical seal

• Comply GMP standards

• Metal-to-metal sealing discharge valve

PROCESS STEPS DURING FILTRATION (& DRYING)

- CHARGING & FILTRATION :

Filtration depends very much on the characteristics of the products. Filtering experience can be gained by carrying out tests in small-scale lab units. Experience has shown that the majority of filtrations are done in the range of 1.5 to 2.5 bar. To assist in filtration, vacuum can also be pulled underneath the filter media.

- DRYING UNDER VACUUM :

Drying is aided by vacuum, heatable blades, half pipe coil on the shell and Heatable filter plate. All around heat input ensures very efficient drying under vaccum A bag or cartridge dust filter is installed on the top Cover to trap and return any dust entailed in the vapor exiting the vessel.

- WASHING/RE-SLURRY

The ideal washing procedure is established by trials. Less porous, Crystalline particles usually need a displacement washing while porous, lamina-like products are preferably washed through a re-slurry washing.

However, in many cases a combination of both show the best results.

- DISCHARGE

Cake is discharged automatically by opening the discharge valve and rotating the agitator, thereby avoiding operator contact. Discharging can be done in an inert atmosphere for the further processing of the cake. The rate of discharge can be controlled by varying the speed of agitator lowering and speed of rotation.

- CAKE PRESSING/ SQUEEZING

Cake pressing is done to remove any cracks formed on the cake. This is effected by applying pressure on the cake surface by means of the agitator. After final washing, the cake can be squeezed by this method to allow further de-watering, reducing the residual moisture content.

- ANF/ANFD ADVANTAGES

Maximum safe operating environment for product & operator

Toxic & hazardous material/product can be processed with washing & repeat washing with water/solvents

Maximum heel recovery of product

Reduced product contamination & Reduction in Capital cost due to multiple operations such as Crystallization,

Intermediate hold Essel Re-slurry Vessel & Drying within single unit.

Bulk quantities can be processed in a single bath & hence reduced filtration & drying times.

Easy discharge of cake/powder compared to other filters/dryers.

Full automation is possible

Conclusion:

The Agitated Nutsche Filter and Dryer represent a significant advancement in industrial processing, offering a holistic solution for solid-liquid separation, washing, and drying within a single vessel. The incorporation of agitation into the design enhances the efficiency of filtration and drying processes, making these units indispensable in various industries, including pharmaceuticals, fine chemicals, and specialty chemicals. The Agitated Nutsche Filter and Dryer not only streamline production processes by combining multiple steps into one but also provide several key benefits. The ability to achieve continuous filtration, high throughput, and low cake moisture levels after drying underscores their efficiency and reliability. The gentle handling of solids through agitation prevents damage, ensuring the quality of the final product.